Kern Maschinen

Flexible Maschinen für Ihre zukunftsorientierte Fertigung

.webp)

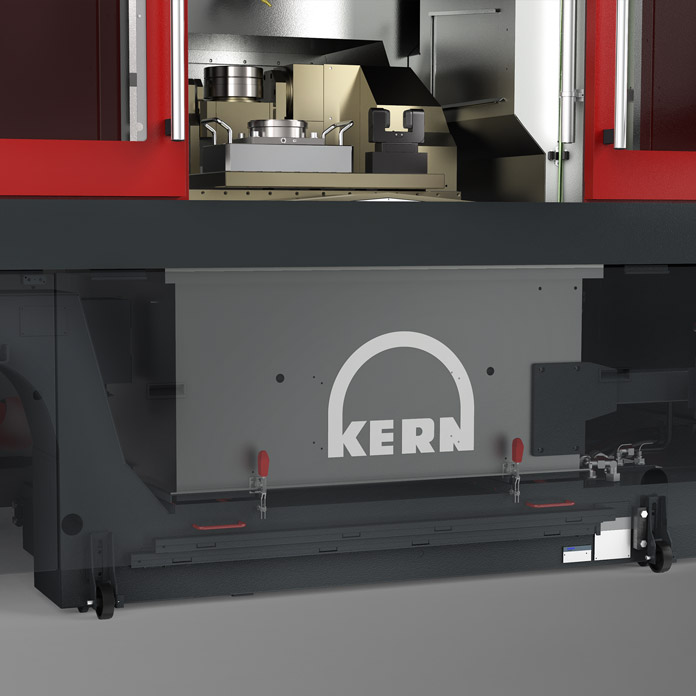

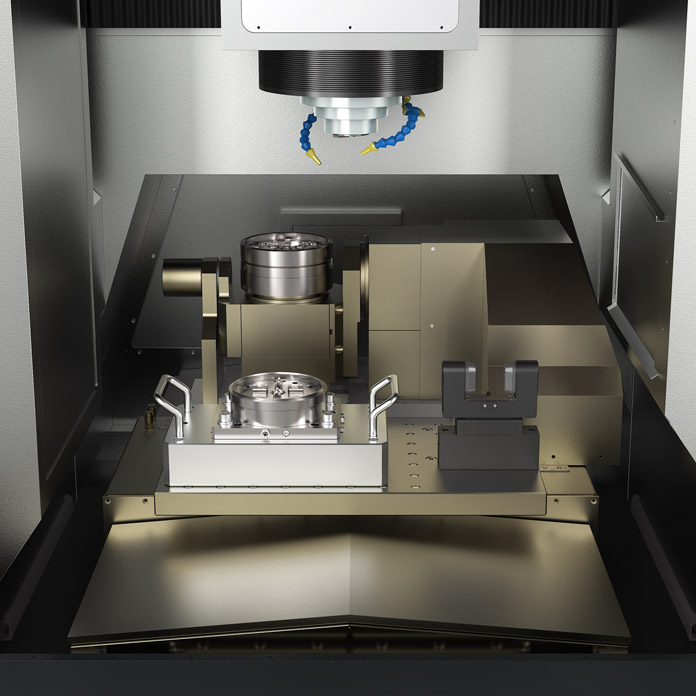

Kern Micro Plattform

Ob Einzel- oder Serienfertigung – wenn es um höchste Präzision geht, ist die Anschaffung eines Bearbeitungszentrums von Kern Microtechnik das Richtige. Insbesondere durch die Kern Micro Plattform lässt sich die optimale Maschine für Ihr spezifisches Anwendungsspektrum konfigurieren und individuell in Ihre Fertigung integrieren. Wir sind spezialisiert auf flexible Maschinen für die Serienfertigung.

Kern

Klassiker

Das Bearbeitungszentrum Kern Pyramid Nano hat bereits eine lange Tradition im Hause Kern und ist vom Markt nicht mehr wegzudenken.

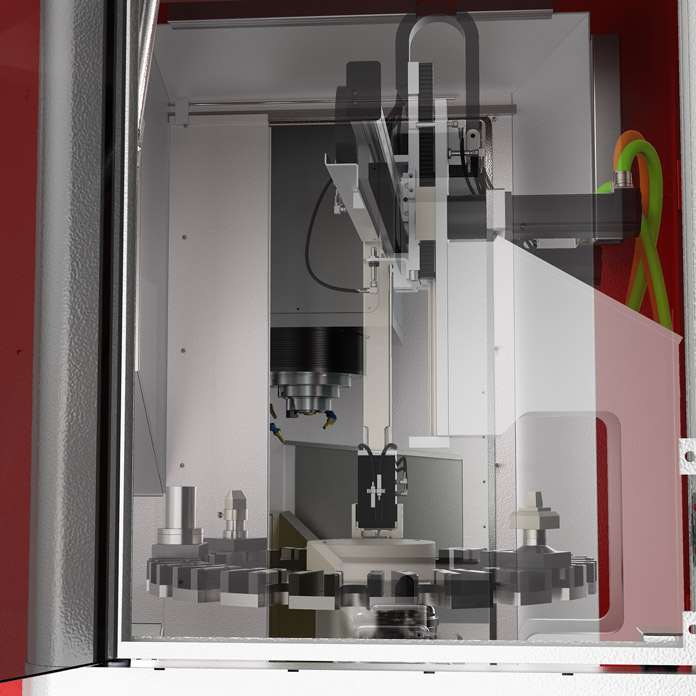

Kern Femto E3

Kern Femto E3

Die Kern Femto E3 ist ein 3-Achs-Laserbearbeitungszentrum, welches mit einer Femtosekunden-Laserquelle ausgestattet ist und komplexeste Werkstoffe bearbeitet. Die Maschine basiert auf einer bewährten, hochpräzisen Kern Maschinenplattform und modernster Steuerungssoftware für die Lasermikrobearbeitung.

Das System ist für die präzise Lasermikrobearbeitung von kleinen Werkstücken ausgelegt. Im Gegensatz zu herkömmlichen Fräsmaschinen zeichnet sich die Kern Femto E3 durch folgende Punkte aus: geringer Energieverbrauch, benötigt kein Öl oder sonstige Flüssigkeiten, keine Späneabfuhr und niedriger Geräuschpegel. Dies macht die Kern Femto E3 zu einem nachhaltigen Produktionssystem.

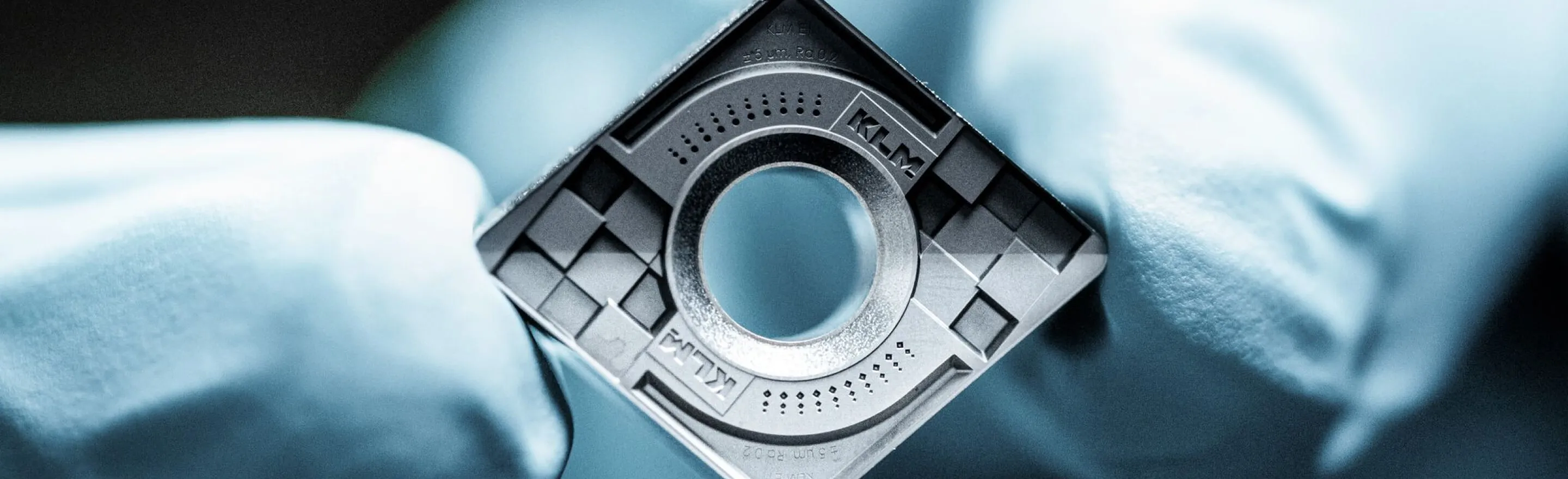

Prozessentwicklung

Zur Steigerung Ihrer Produktionskapazitäten bietet Kern Microtechnik nicht „nur“ seine Maschinen, sondern auf Wunsch auch den kompletten Fertigungsprozess für

Ihre Teile an.

Können wir auch Sie bei der Umsetzung eines Teiles unterstützen? Kontaktieren Sie unsere Spezialisten

und entdecken auch Sie das Kern Potenzial!

Training Center

Als autorisierter Schulungspartner der Firma Heidenhain bieten wir Heidenhain-Kurse für Einsteiger, Anwender und Profis an. Zusätzlich können auch Schulungen zur Bedienung der KernMaschinen, als auch technische und kundenspezifische Schulungen gebucht werden.

Broschüre downloadenMaschinensupport

Unser klares Ziel im Kern Service ist die Verlässlichkeit, weltweit. Egal ob bei bereits gekauften oder neuen Kern Maschinen: im Notfall, bei Veränderungen oder Weiterentwicklungen – auf uns ist Verlass.

Mehr erfahren